BY JOE GATTO

Warehouses are in a period of transition where they seek to rapidly shift away from very low rates of adoption of automation. According to Lisa Chai, partner and senior research analyst at ROBO Global, 80% of warehouses today have no automation at all. Another 15% have some automation, while a small 5% have implemented more advanced technologies. The Logistics Management’s Annual Warehouse and Distribution Center Automation Survey found that only 4% of companies consider their fulfillment operations to be “highly automated.”

The current state of automation is unsustainable as crushing spikes in labor rates and a chronic shortage of workers paralyze the warehouse industry. According to Berkshire Grey’s survey 2022 State of Retail & eCommerce Fulfillment Report, more than half of executives surveyed (57%) believe labor shortages have hindered their ability to meet demand, with an annual labor turnover of 300 percent.

It’s high time for warehouse automation

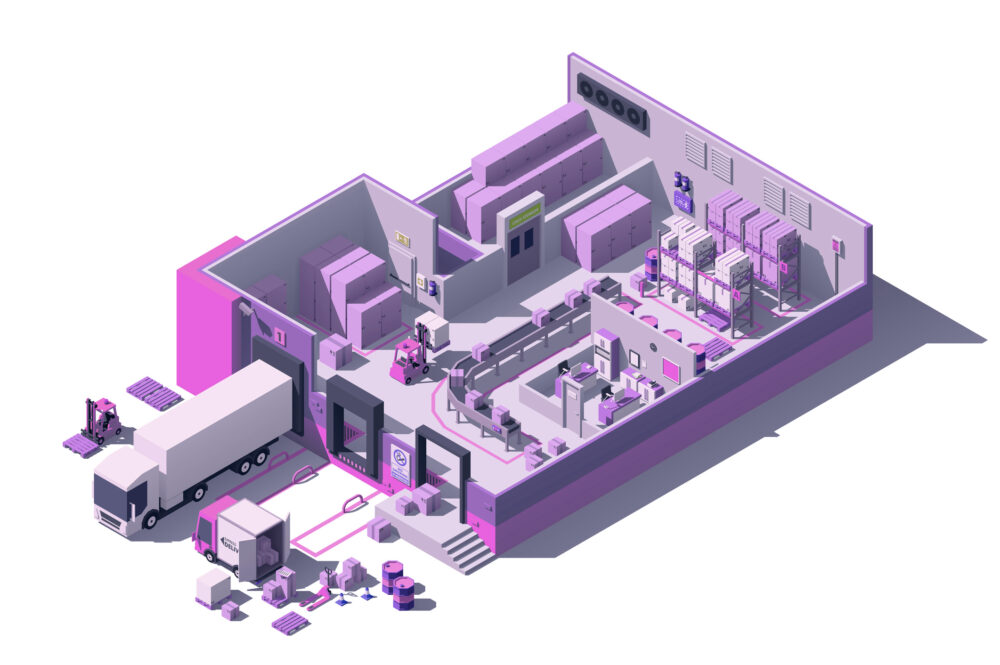

Digital innovations are a pressing need to lower costs and create flexible operating systems to cope with fluid warehouse environments. The 2022 MHI-Deloitte survey of warehouses found that the Covid epidemic drove 78% of respondents to increase their adoption of supply chain innovations. Some warehouses have increased the adoption of automated guided vehicles, robots, and forklifts to save labor costs. A CBRE report quoting industry studies predicts productivity gains of up to 46% in distribution centers using automation and robotics technology.

The expected adoption in the next five years is significantly higher than its current state, as described below:

The adoption of digital innovation and its future rise will have an increasing need for flexible mobile networks which use programmability, virtual network functions, and cloud-native technologies to reconfigure existing network infrastructure for various purposes at a much lower cost.

Warehouse automation needs a programmable private mobile network at the edge

Networks play a critical role in accelerating the adoption of digital technologies. Many warehouses use fixed networks or Wi-Fi rife with interference, security concerns, non-deterministic communications, and limited mobility. It prevents warehouses from fully realizing the benefits of innovative technologies like robotics, drones, IoTInternet of Things – Physical objects with the ability to connect and exchange data with each other over the Internet. A network of objects that are embedded with sensors, processing ability, software, to connect to and exchange data with other such objects or networks. More, predictive analytics, and more.

Private 4G/5G networks offer deterministic performance, ubiquitous mobility, robust security, higher reliability, and software-defined agility required by warehouse automation. Newer programmable private mobile networking technologies at the edge use developer-friendly APIs to integrate with warehouse IT systems and provide real-time data to OT applications to direct the movement of shipments flexibly.

In fact, developer-friendly APIs for configuring and managing private networks improve the business case for digital innovation. Network APIs automate routine network provisioning tasks and cut costs of manually configuring network devices, managing user device lifecycle, ensuring the quality of service, and enforcing consistent security policies.

Programmable private mobile networks are pivotal to productivity and safety in warehouses

Private 4G/5G networks help speed up warehouse operations, synchronize activities, and make them safer. To begin, they provide automated means using eSIMEmbedded Subscriber Identity Module – A piece of software that can be used instead of a physical SIM to establish connectivity between user equipment and the eNodeB of a mobile service provider. More cards to identify and authenticate temporary workers for holiday seasons, new hires, and IoT devices.

As the adoption of robots rises rapidly, the risk to human safety grows disproportionately due to the expanding numbers of moving devices in warehouses and the faster pace of work. Approximately 11% of forklifts in the United States are involved in an accident each year. Consequently, more work is transferred to Autonomous Mobile Robots to reduce human exposure to injury.

Increasingly, mobile robots are becoming more environmentally aware and intelligent with computer vision, radar, and sensors. An emerging class of robots is risk-sensitive and attempts to find the safest routes. However, such robots consume enormous bandwidthBandwidth is the maximum rate of data transfer across a given path. Bandwidth may be characterized as network bandwidth, data bandwidth, or digital bandwidth. It generally refers to the size of the pipe and the speed that carries the data back and forth, not necessarily the volume of traffic that passes through. More on wireless networks and require low latencies for their remote control. Programmable private 5GThe “G” in 5G stands for generation. 5G is the fifth generation of wireless technology. 5G is characterized by bigger channels (which improves throughput), lower latencies allowing for real time applications, and the ability to connect more devices (which is increasingly important as the number of devices has grown exponentially). More edge networks can ensure the required quality of service for automated operations.

By leveraging 5G networks and distributing computing power across the near edge, far edge, and cloud, warehouses can lower the cost and speed of response, making automated warehouses viable.

Private mobile networks improve tracking and monitoring inventory for fulfillment

Fulfilling customer demand at a low cost requires accurately tracking and replenishing inventory before it falls short and frustrates customers. Conversely, warehouses don’t want excessive inventory that does not match current market demand. Warehouses require real-time analytics from IoT devices to speed up laborious processes such as product and pallet matching, especially as they deal with continued disruptions and delays. Nearly 70% of supply chain executives said they need better visibility into the procurement functions of their warehouse, followed by production and labor (65%) and fulfillment (37%).

Optimizing inventory processing with real-time visibility needs uninterrupted indoor and outdoor connectivity that private 4G & 5G networks can provide.

Conclusion

Warehouse automation needs institutions and entrepreneurs bold enough to cope with technological innovation challenges. New methods such as programmable mobile networks, recourse to digital automation, and willingness to draw emerging technologies such as distributed edge networks are needed to break the vicious circle of underinvestment and outdated technologies.

ALEF’s breakthrough Private Mobile Network as a Service lends warehouses the ability to create, customize, future-proof, and control their private mobile networks with a wide choice of APIs available on its edge platform. It frees them from the barriers of cost and complexity of integrating private mobile networks with existing IT/OT systems and security infrastructure – accelerating the adoption of new business-critical digital applications for optimizing productivity.

Alef’s Private Mobile Network realizes the full potential of 5G and edge computing with its evolving edge fabric for distributed networking, incorporating the near-edge and far-edge for optimal processing of warehouse data traffic and its control.